Reimagine Visual Inspection Analysis with VIA

Non-invasive, Fast, Compliant Particle Detection in Intact Vials

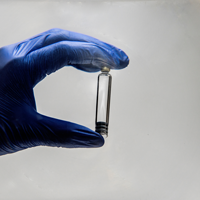

The VIA family of Visual Inspection Analyzers from ImageProVision combines the Nikon SMZ series of stereo microscopes with the particle measurement performance of CLAIRITY™ Particle Analysis Suite to create a unique dedicated solution for supplementary forensic inspection of particulate matter in intact vials, prefilled syringes, and other sealed translucent vessels. VIA offers both manual and automated stereo microscopic inspection of intact vials - without the need to remove contents from the container - for detection of particulate matter. With three deployment options, VIA can be deployed across locations to support supplementary inspection protocols as a cost-effective, globally integrated measurement capability.

VIA System Configurations

VIA from ImageProVision combines the performance of CLAIRITY™ Particle Analysis Software Suite with a Nikon SMZ Stereo Microscope. Designed specifically for supplemental forensic inspection of particulate matter in intact vials and other close containers, without removal of the sample.

There are three models in the range, starting with a budget friendly system which can be deployed in volume, to a high performance system with full automation.

VIA PLUS

Package Details

Maximize efficiency for dedicated analysis

-

Routine particulate matter

investigation in laboratory

or plant QC operations. -

The power of CLAIRITY™ PARTICLE with a NIKON SMZ1270i stereoscope.

VIA STAR

Package Details

Advanced features in a cost-effective model

-

Excellent performance, upgradeable system identification of particulates.

-

The power of CLAIRITY™ PARTICLE with a manual NIKON SMZ18 stereoscope.

VIA DIAMOND

Package Details

For the most demanding applications

-

Highest performance, automation and measurement flexibility.

-

The power of CLAIRITY™ PARTICLE, CLAIRITY™ AUTO with a NIKON SMZ25 stereoscope.

“The VIA platform provides a useful orthogonal capability in our visual inspection protocols. When the results are ambiguous, or need further investigation, the VIA system provides particle information to identify contributing sources to support continuous process improvements.”

Supplementary Forensic Inspection

Pharmaceutical product defects such as the presence of particulate matter can lead to significant consequences including patient safety issues, and product recalls. While automated visual inspection is the primary method for identifying these type of defects, its primary objective is detection not identification of particulates. Supplementary forensic inspection techniques focus on the detection of complex defects that may be missed by automated systems, and forensic identification of contaminants for traceability and preventative measures.